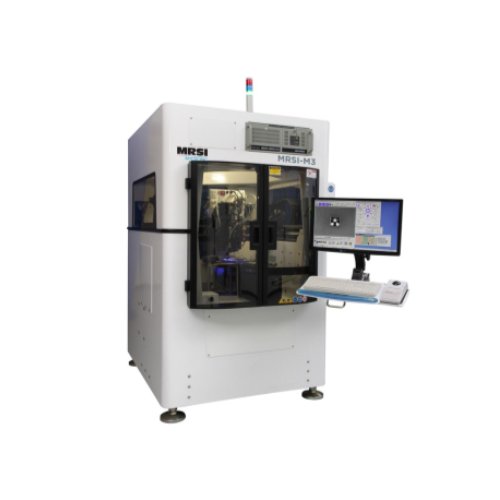

3um Die Bonder

Model:MRSI-M3

The MRSI-M3 3-Micron Die Bonder sets the industry standard for ultra-precision, high-complexity die attach in high volume production environments. With features such as force control, ultra precise placements, and 360° die orientation, the MRSI-M3 die bonder ensures high yields, high quality and high reliability in advanced packaging.

The highly configurable, MRSI-M3 platform ensures optimum asset protection. The system delivers an unmatched combination of 3-micron accuracy, automation, speed and reliability; in-situ assembly processes such as eutectic die bonding, UV epoxy die attach and flip chip assembly are all possible. The MRSI-M3 3-Micron die bonder is ideally suited for manufacturers of microwave modules, IR sensors, MEMS, multi-chip modules, stacked assemblies, hybrid devices and photonic packages.

From small dies to large sensors, the MRSI-M3 3-micron die bonder provides all the capability and flexibility to assemble the most advanced packages, without compromising on manufacturing efficiency, quality and reliability.

Benefits

The MRSI-M3 uses an advanced cast composite base, enabling fast and accurate moves with virtually no settling time. The large work envelope enables a wide range of configurations (see options tab) to meet customer requirements.

Advanced functionality equates to significant benefits:

- High Speed AND High Accuracy – An advanced axis system driven by brushless DC linear servomotors with linear glass-scale encoder feedback for high speeds and accurate movements.

- High Machine Efficiency AND High Product Quality – Built-in internal temperature monitoring ensures consistent placement. Known heat sources, such as motors are designed with gas cooling; ensuring that thermal expansion is kept to a minimum.

- Optimum Placement Yields – The system’s closed-loop force control enables placement of delicate Gallium Arsenide (GaAs) dies with as little as 10 grams of force. At the other end of the scale, forces up to 2kg are programmable.

- Flexible Component Supply Options – Die are picked from waffle pack ,Gel-Pak®, wafer, tape and reel and custom trays.

- Maximum Asset Use – MRSI-M3 machines are designed to handle a wide range of processes. Epoxy dispensing pumps, epoxy stamping and eutectic bonding with scrub and temperature control, are all configuration options that make the MRSI-M3 3-micron die bonder a complete assembly solution (see features tab for details).